Hi Folks,

I picked up four Chevy Volt Lithium Battery Packs converted to 12 Volts each rated at 200 AH. The batteries have liquid cooling, which I plan to use. The batteries also have a temperature sensor, so I will be able to monitor the battery temperature. There really isn't any off the self Battery Management Systems (BMS) that will work with Chevy Volts batteries outside being in a Chevy Volt. The little I could find out was that very max cell voltage is 4.2 volts per cell; however, if you charge them that high, you will shorten the lifespan to less than 4-5 years. Charging the batteries to 4.02 volts per cell, the batteries will last 15-20 years. Charge them to 4.1 volts per cell, and the lifespan drops to 7-8 years.

I haven't found any data on max temperature, but some folks say keep them under 90 degrees. I plan to keep my battery cell voltage between 3.3 Volts and 4.01 Volts, which I can adjust in the program, once I get some real world use.

Speaking of program, my BMS is home grown, using Arduino Mega microprocessor.

|

| Arduino Mega Microprocessor 256 KB Memory 16 Analog Inputs and 54 Digital Input/Output Pins |

I added off the self Ethernet board that plugs right into the Arduino, and I added two prototype boards with my circuits to measure cell voltage, battery temperature, total battery voltage and Boostcaps voltage.

|

| In case you wonder what a Boostcap is, here you go, I will explain later why you need them. |

|

| Here is the side view of my four Chevy Volt battery packs. Two packs are connected together to make two 400 AH battery packs. |

|

| Battery Management connections. One for each pack. |

|

| Here is two packs connected to the BMS. |

|

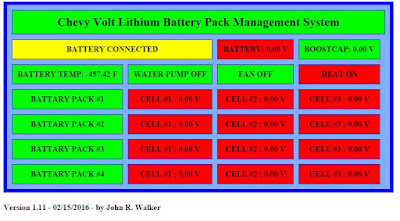

| Here is the Battery Management System web page I programmed for the two battery packs above. |

|

| Here is the completed BMS web page, with batteries not connected. |

OK, so the why do we need the Boostcaps? There two reasons, the solar controller isn't really made for Lithium batteries, and neither is the Montana's converter (converts 120 volts AC to 13.5 Volts DC). Lithium battery will charge a very high rate, but when they reach the charge voltage, you need to stop charging them. The most common RV batteries are Lead Acid, AMG, and Gel batteries, which you have to hold a high voltage of charge for 3 hours to fully charge them. These type of batteries require 15% more power put into them, than you get back out. Also only 50% of AH capacity can be used. The number of cycles is around 500.

With Lithium batteries, you get the same amount of power out as you put back in. Lithium batteries can safely use 80% of AH capacity, and number of cycles is 3,000 to 4,000. If not pushed beyond the 4.02 volts per cell, battery temperature maintained, the batteries could last 15-20 years.

The drawback to Lithium batteries, is you must have special charging systems that manages the charging, discharging of the batteries, and keeps the cells balanced.

So now we come to the Boostcaps, to trick the dummy charger into thinking it is charging a Lead Acid battery. The Boostcaps are very low voltage (2.7V) so putting six in series the can handle 16.2 volts with millions of cycles. I don't know how many Amp Hours are in the Boostcaps, but the can deliver 1,000 Amps for short period of time, and recharge in seconds when connected to a battery.

Since the solar controller can be damaged if disconnected from the batteries while the solar array is making power, the Boostcaps provide a battery like equivalent, and everyone is happy.

Now we need a way to connect the batteries to the Boostcaps when the batteries need charging, and to disconnect when fully charged. And if the Boostcaps voltage drops below the battery voltage (meaning no more solar power or load is greater than solar output), we need to connect the batteries to recharge the Boostcaps. We also need to make sure no battery cells drop below the set value in the BMS parameters.

|

| Here is the Arduino, with my two prototype boards and the battery balancer. When all four packs are hooked up there will be four battery balancers plug into the two prototype boards. |

Although I have already prototype'd the Fan, Pump, and Heater controls, I need to put those circuits my finished prototype boards.

I also need to build a insulated battery box to keep batteries warm. After that I will need to plumb the cooling lines, pump, and radiator to keep then cool.

|

| Battery heat, pump and fan circuit. |

|

| Here I have just the Boostcaps connected so I and test the new circuits I built tonight (2-23-2016). Also test low and high voltage disconnects. The light will be my heat source. |

|

| Here you can see the three MOSFITS that control the Heat (three light bulbs), water pump, and fan on the radiator. |

|

| This is my electric water pump from a Priest. |

|

| I got a small radiator with electric fan. |

More to come....